Home » 50hz- Engineered Pumps

Sewage & Drainage

VT Series

VSP Series

VT Series

The VTP Series vertical turbine pumps stand at the forefront of pump technology, boasting a single-stage or multistage design meticulously crafted to manage significant water level fluctuations effortlessly, eliminating the need for priming. These pumps feature mixed or axial flow impellers to accommodate high flow requirements, making them adaptable for both wet and dry pit applications. The design incorporates line shaft bearings with options for self or external cooling, ensuring efficient operation across diverse conditions. Moreover, a ratchet arrangement prevents reverse rotation, bolstering operational reliability. With these advanced features, the VTP Series is well-suited for a myriad of applications, ranging from water intake and fire fighting to intricate water management systems in power plants and refineries.

Applications

- Raw water

- Irrigation

- Power plant

- Water treatment plants

- Municipal water supply

- Dock yard

- Flood Control

- Fire fighting

Key Features

- Different material option

- Wide hydraulic ranges

- Dynamically balanced rotating parts

- Optional surface coating for efficiency improvement

All you need to know about – Industrial Pumps (VTP Series)

Specifications

| Standard | Manufacturer Standard |

| Head | Up to 250 m |

| Maximum Flow | Up to 16000 m³/h |

| Speed | 720/960/1450/2900 RPM |

| Impeller Type | Enclosed Impeller |

| Outlet Size | Up to 900 mm |

| Power | Up to 2400 kW |

| Liquid Temperature | Up to 90°C |

| Max Solid Size | Not Applicable |

| Shaft Seal | Gland Packing, Mechanical Seal |

| Material of Construction (MOC) | Cast Iron, Bronze, Stainless Steel & Alloy Steel |

| Bearing Lubrication | Line Shaft – Self & External Lubrication Thrust Bearing – Grease or Oil |

| Flange Standard | DIN |

| Maximum Working Pressure | Up to 25 bar |

Material of Construction

| Part Name | Material |

|---|---|

| Impeller | SS 304 / Noryl / Cast Iron |

| Bracket | Cast Iron |

| Casing | Cast Iron |

| Motor Shaft | SS 410 |

| Motor Body | SS 304 |

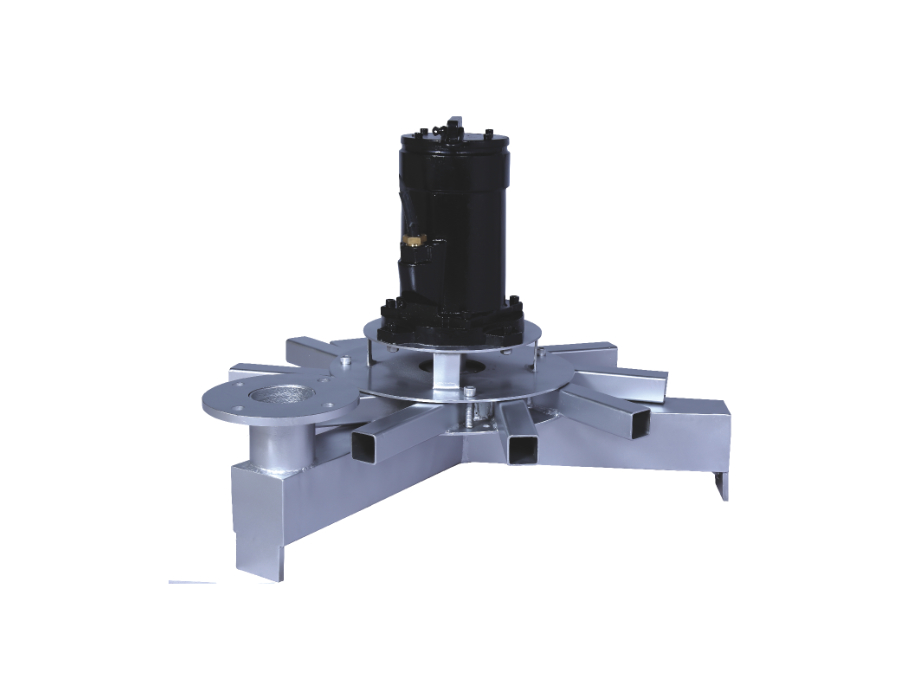

VSP Series

Engineered to tackle the most demanding fluid management tasks, our Vertical Sump Pumps are a cornerstone in industrial operations worldwide. These pumps feature end suction configurations, optimized for vertical installation as sump pumps, making them ideal for a diverse array of challenging liquid handling applications. With the flexibility to handle various types of liquids, our pumps are meticulously designed with enclosed or semi-open impellers and can be customized with different materials of construction to meet specific industrial needs.

Applications

- Industries

- Waste water draining

- basins

- Low density slurry

- power plant

- Water treatment plant

Key Features

- Compact and space saving construction

- Designed to meet Specific lengths & application requirement

- Pump shaft provided with cutless rubber and composite bearings

All you need to know about – Industrial Pumps (VS Pumps)

Specifications

| Standard | Manufacturer Standard |

| Head | Up to 110 m |

| Maximum Flow | Up to 1500 m³/h |

| Speed | 720 / 970 / 1450 / 2900 RPM |

| Impeller Type | Semi Open / Enclosed |

| Outlet Size | Up to 250 mm |

| Power | Up to 200 kW |

| Liquid Temperature | Up to 100°C |

| Max Solid Size | Up to 60 mm |

| Shaft Seal | Standard – No Seal Optional – Mechanical Seal for Hazardous Liquids |

| Material of Construction (MOC) | Stainless Steel & Alloy Steel |

| Bearing Lubrication | Line Shaft – Self & External Lubrication Thrust Bearing – Grease or Oil |

| Flange Standard | DIN / ANSI |

| Maximum Working Pressure | 16 bar |