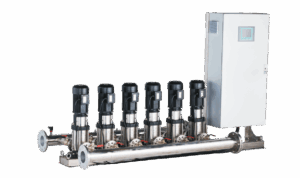

Pressure Booster Pump (Mvhs)

The MVHS SERIES Pressure Booster System by CRI is the premier choice for efficient water pressure management in commercial, industrial, and residential settings. With a remarkable flow rate of 1200 m³/h and a head of up to 300 meters, this system ensures optimal water pressure management across a wide range of applications. Engineered with advanced IMS logic and cascading operation, the MVHS SERIES offers seamless and reliable automation, ensuring low noise, minimal maintenance, and cost-effective performance. Constructed with high-quality stainless steel, galvanized iron, and nickel-plated components, this system guarantees exceptional durability and longevity. Safety features such as pump dry run protection, overload protection, and low-pressure protection enhance operational reliability, making the MVHS SERIES ideal for demanding commercial and industrial environments.

Applications

- Commercial Buildings & Residential Building

- Irrigation Systems

- Industries

- General Public Sector

- Water distribution & Tank filling

Key Features

- Powered by IE5 Motors

- Dedicated IMS Logic

- Low-pressure Protection

- Shorter downtime

- Modbus RS485 communication Protocol

- Protection Functions

- Alarms - Visual/Audible

- Communication Protocol

- Protection Functions

- Alarms - Visual/Audible

- Communication Protocol

- Protection Functions

- Alarms - Visual/Audible

- Communication Protocol

All you need to know about - Pressure Booster (MVHS Series)

OPERATION RANGES

| Max. Flow | 1200 m³/h |

| Max. Head | 300 metres |

| Max. Power | 110 kW |

| Max. Liquid Temperature | 70° C |

| Speed in RPM | 2900 |

Material Of Construction

| Pump | SS |

| Valves | Nickel Plate / CI / SS |

| NRV | Brass / CI |

| Base Frame | GI / SS |

| Manifold | GI / SS |

You might also like

How can we support you?