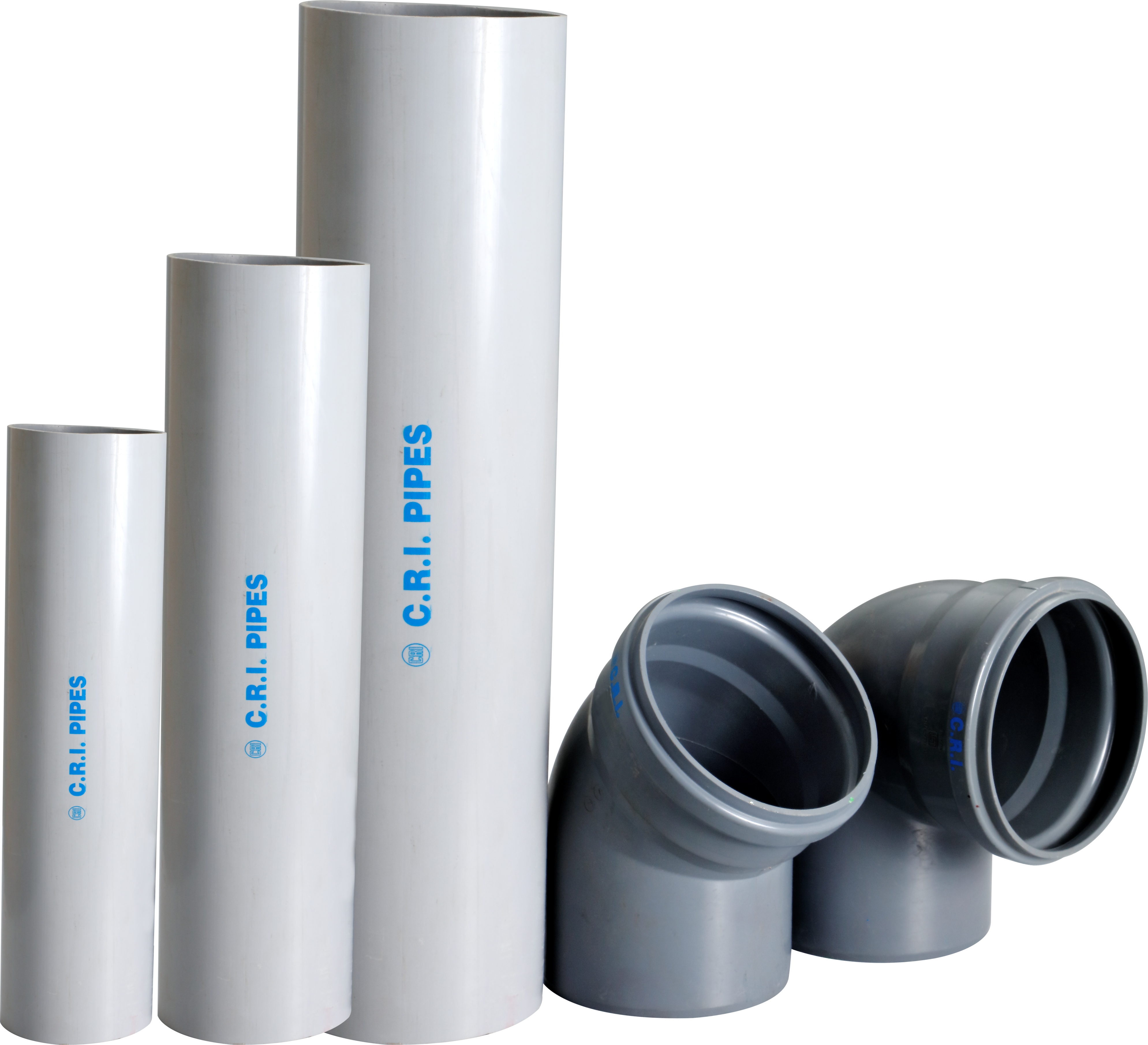

UPVC SWR PIPES & FITTINGS

Introducing CRI’s uPVC SWR Pipes & Fittings, Precision-Engineered for Superior Drainage. Designed to meet IS 13592:2013 standards, CRI’s uPVC SWR Pipes & Fittings embody technical excellence for efficient waste and rainwater management. Available in 75mm to 160mm diameters, our solutions are tailored for diverse applications. Their anti-corrosive properties and high impact resistance ensure robust performance, making them suitable for industrial to residential use.

Applications

- Industries

- Agricultural

- Hotels

- Apartments

Key Features

- Chemical Properties: Non-corrosive, ensuring a longer life cycle

- Physical Properties: Lighter in weight than conventional metal pipes; allows for easy handling, transportation, and installation

- Longer Life: Life cycle of up to 50 years, saving on replacement and replenishment costs

- Anti-Corrosive & Non-Conductive: Offers excellent life by avoiding electrochemical reactions

- Convenient and Reliable: Provides easy and stronger joints, with adequate access for cleaning and clearing obstructions

- Less Maintenance: Once installed, the C.R.I. SWR drainage system requires minimal or no maintenance

- Cost-Effective: The SWR drainage system is more cost-effective than conventional drainage systems

All you need to know about - uPVC Swr Pipes & Fittings

Specifications

| NOMINAL DIAMETER DN |

MEAN OUTSIDE DIAMETER OF PIPE |

OUTSIDE DIAMETER OF PIPE AT ANY POINT |

WALL THICKNESS | |||

|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Min. | Max. | |

| 75 A | 75 | 75.3 | 74.1 | 75.9 | 1.8 | 2.2 |

| 75 B | 75 | 75.3 | 74.1 | 75.9 | 3.2 | 3.8 |

| 90 A | 90 | 90.3 | 88.9 | 91.2 | 1.9 | 2.3 |

| 90 B | 90 | 90.3 | 88.9 | 91.2 | 3.2 | 3.8 |

| 110 A | 110 | 110.4 | 108.6 | 111.4 | 2.2 | 2.7 |

| 110 B | 110 | 110.4 | 108.6 | 111.4 | 3.2 | 3.8 |

| 160 A | 160 | 160.5 | 158 | 162 | 3.2 | 3.8 |

| 160 B | 160 | 160.5 | 158 | 162 | 4.2 | 4.8 |

| Component | Material |

| Check valve housing | Cast iron |

| Outer shell | Stainless Steel |

| Impeller | Noryl |

| Diffuser chamber | Noryl |

| Counter thrust pad | Hylem |

| Intermediate bearing (Sleeve / Bush) | SS – 304 / NBR |

| Suction inter connector | Cast iron |

| Pump shaft | SS – 304 |

| Coupling | SS – 410 |

Material Of Construction – Motor

| Component | Material |

| Stator shell | SS 304 |

| Shaft seal | Nitrile Butyl Rubber / Mechanical Seal |

| Motor base | Cast iron |

| Motor Shaft | SS – 431 |

| Bearing | SS Ball Bearing |

| Snap Ring | SS – 316 |

You might also like

How can we support you?