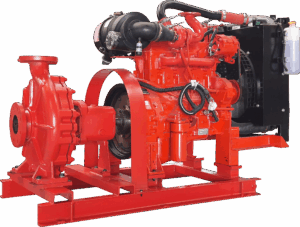

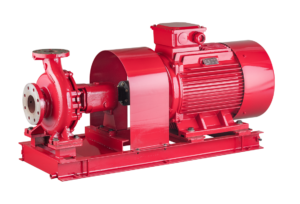

Fire Fighting

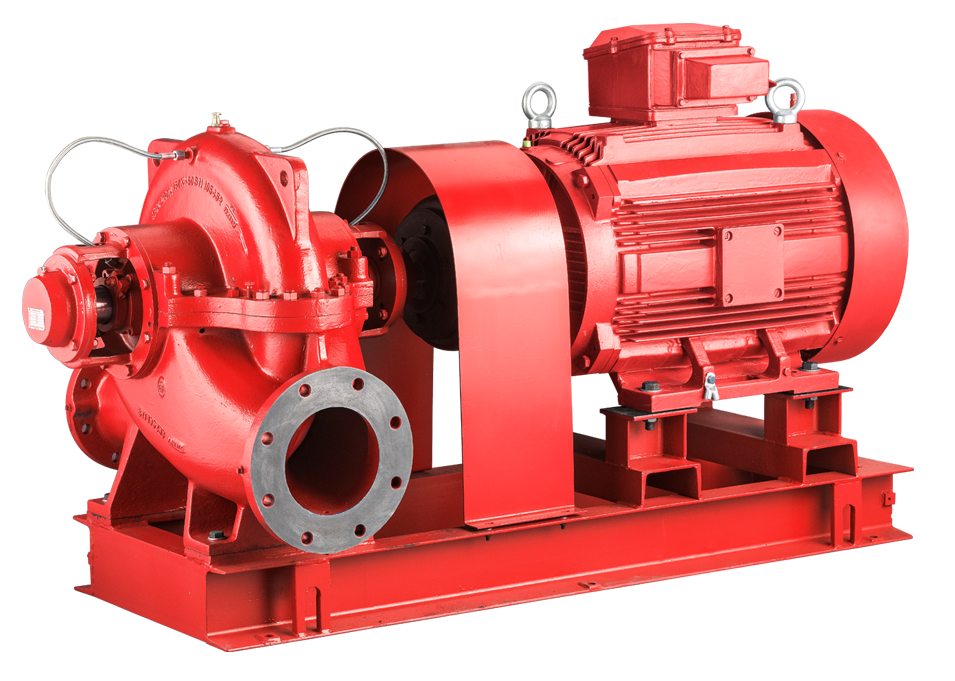

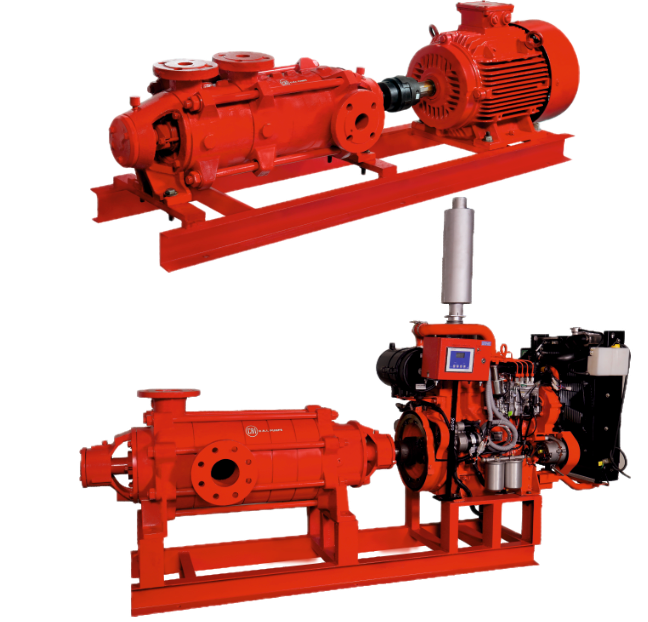

ECW system with Motor and engine

- Patented design – Serrated & double flat Impeller nut

- Patented design – Stuffing box for Efficient cooling

- Designed to allow interchangeability of components across the pump sizes.

- Minimized shaft deflection prolong the life of the mechanical seal and bearing.

- Back pull out design facilities dismantling the pumps without disturbing the Piping

- Dimensions and characteristics according to DIN 24255 standards Available both in mechanical seal and soft packed stuffing box design.

- Optimized performance and maximum efficiency reduce the operating cost.

- Low noise & vibration levels lead to be environment friendly.

Applications

- Process industries

- Water Supply

- HVAC

- Modern Irrigations

- Pressure Boosting Industrial Utility

- Fire Fighting Cooling Towers

Key Features

- Pump Operational

- Pressure Feedbacks

- Protection Functions

- Alarms- Visual/ Audible

- Communication Protocol

All you need to know about - Fire Fighting ECW system

Specifications

| Max. Flow | 550 m³/h |

| Max. Head | 120 metres |

| Max. Power | 160 kW |

| Max. Liquid Temperature | 90° C |

| Speed in RPM | 1450 /2900 |

| Max. Pump Size | DN 150 |

Material Of Construction

| Max. Flow | 1200 m³/h |

| Pump | SS |

| Max. Head | 300 metres |

| Valves | Nickel Plate / CI / SS |

| Max. Power | 110 kW |

| NRV | Brass / CI |

| Max. Liquid Temperature | 70° C |

| Base Frame | GI / SS |

| Manifold | GI / SS |

| Pump Casing | C.I./CF8/CF8M |

| Impeller | C.I./BZ/CF8/CF8M |

| Shaft | S.S 410/S.S 304/S.S 316 |

You might also like

How can we support you?